Pretreatment Chemicals

Pretreatment Chemicals

Pretreatment Chemicals

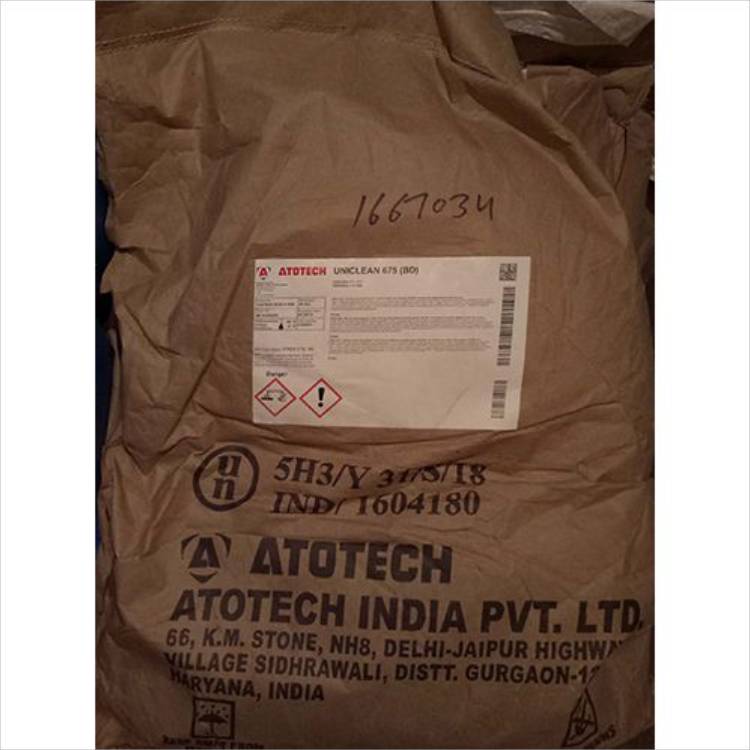

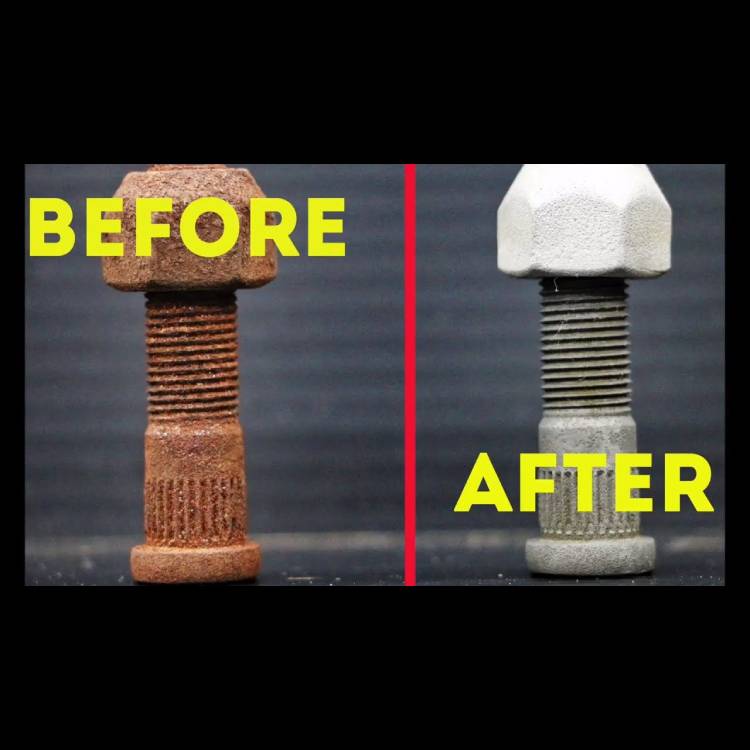

Pretreatment is the preparation of a feed, be it metal, before the actual reaction that needs to be carried out for enhancing the effects of the same reaction. For example, pretreatment, before metal stripping is carried out, involves the immersion of the object in an extremely hot aqueous/alkaline cleaner and then proceeding for cathodic activation in am electro cleaner. In electrocoating pretreatment, a metal is cleaned thoroughly removing specks of dust, rust, and oils for better electro-coated painting where a phosphate or other conversion coating could now be applied. Pretreatment for powder coating follows the same procedure for cleaning the metal layer as it is highly susceptible to atmospheric corrosion.

Pretreatment Chemicals

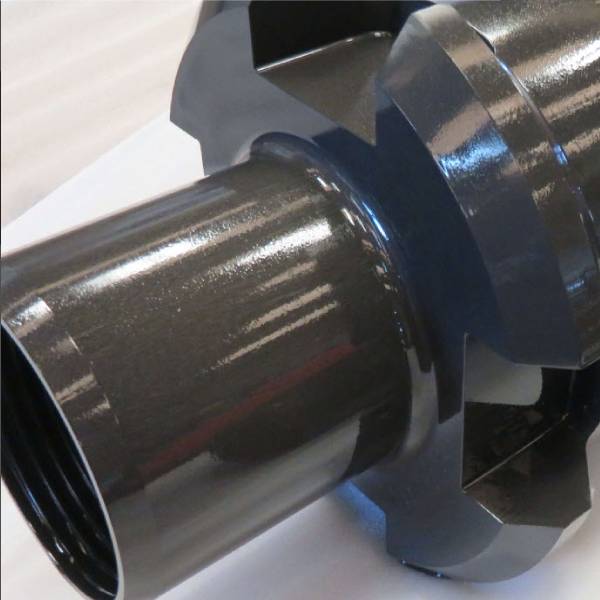

Functional Metal Plating helps in effective prevention of corrosion that enhances and upgrades the conventional methods of coating. These elements are bonded together by the inorganic matrix. This metal plating has influenced and made workings better in the field of engineering practice. Functional metal plating is a thin film being applied to various metals. It is usually liquid and gets dried up easily. Functional Metal plating is aimed at corrosion resistance through inorganic mode.

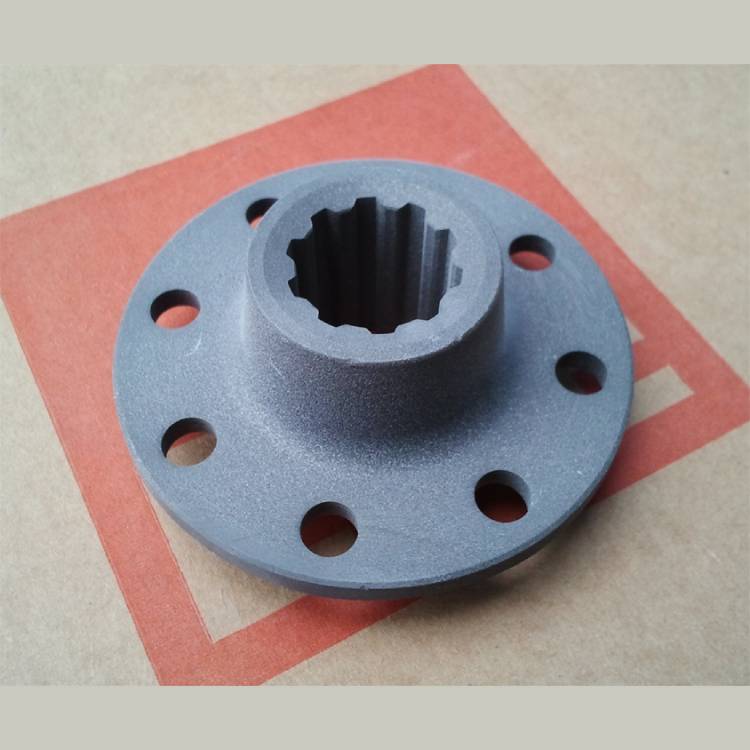

Phosphating

Phosphating refers to the process of creating a porous metal phosphate conversion layer to increase the adhesion of powder coating on steel surfaces.

WANT TO KNOW MORE ABOUT OUR SERVICES

With over 20 years of in-depth experience, ATC delivers cost effective & efficient solutions and can be your ideal

partner for all your metal coating and finishing requirements.