Pickling & Passivation SS/INOX

Pickling and Passivation on Stainless Steel

Stainless steel and Inox pickling and passivation are chemical processes that are utilized to provide protection to metals against corrosion and pitting. In Pickling and passivation process, an acidic solution is used to the metal surface to remove contaminants and process for chromium-oxide passive film after successful removal of Nickel, molybdenum and other metal. Without pickling and passivation, stainless steel is subject to corrosion which can lead to quality issues and job failure.

1. Degreaser

Before pickling or passivation of stainless steel or inox it must to remove processing oils and grease, organic contaminants present on the surface of the metal. If these contaminants are not removed before the pickling and passivation or passivation, it will have an adverse effect and the desired result will not be achieved.

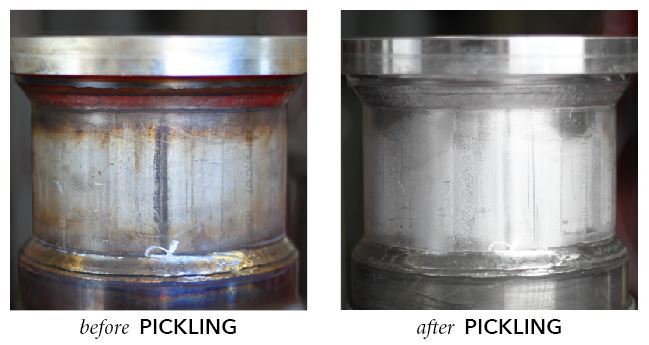

2.Pickling liquid

Pickling Liquid is usually used in tank immersion or circulation and it is advantageous for treating all the fabrication surfaces at the same time for uniformity of finish and optimum corrosion resistance. Pickling liquid is circulated through a system of pipework and is particularly recommended for piping that will carry corrosive liquids.

- A) Fintech 0416

- B) Pick and Pass Liquid

3. Pickling Spray Semi Gel

Pickling spray semi gel is usually recommended for treatment of complete fabricated structures or tanks in which immersion or circulation is not possible. Pickling Spray semi gel has consistency so it can be sprayed with the help of pressure sprayer and it sticks to job for enough time so process gets completed. Pickling Spray semi gel advantageous for on-site treatment but proper acid disposal and safety procedures are essential.

- A) Pick and Pass Spray

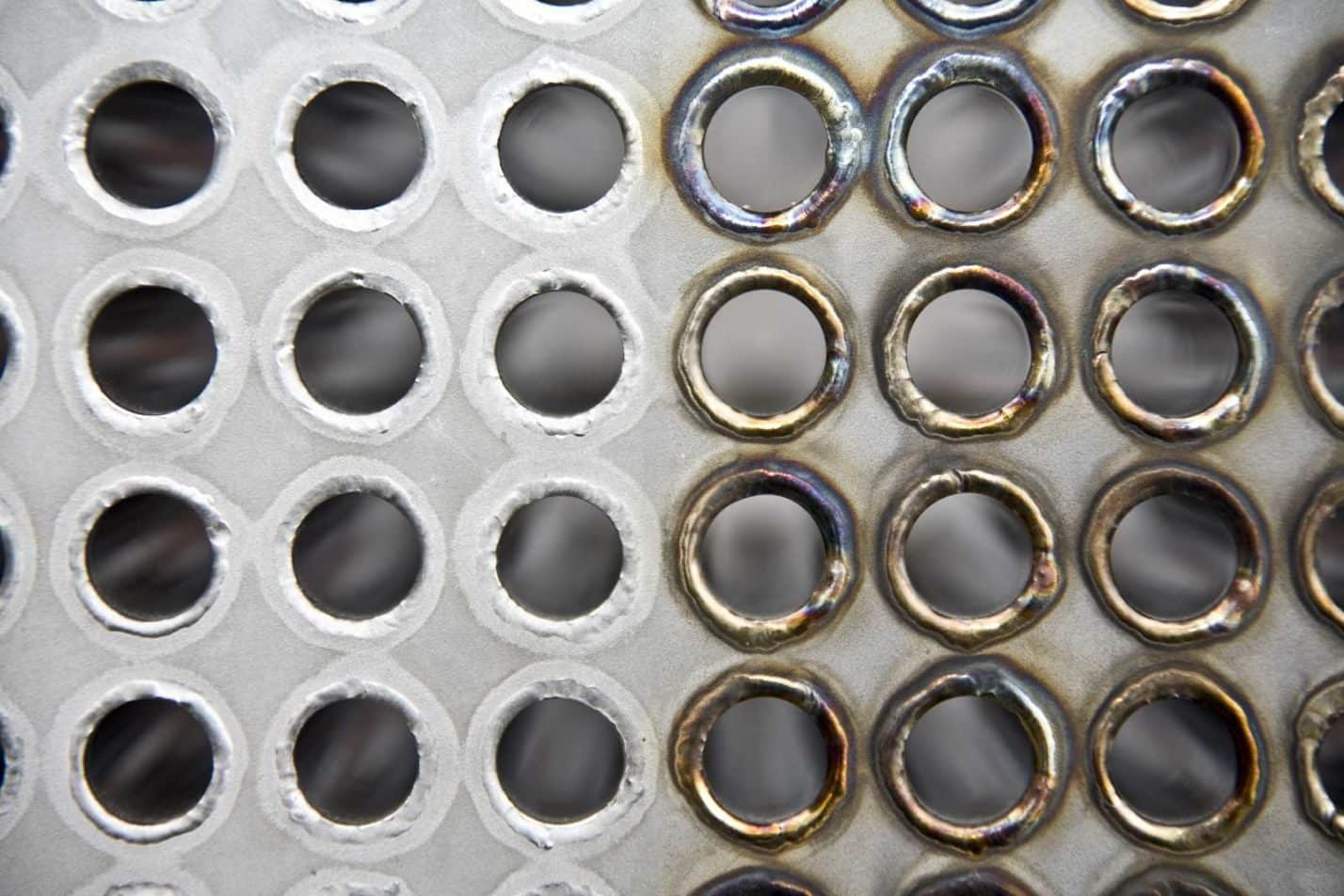

4. Pickling Gel /Pickling paste

Pickling gel or paste is used for cleaning and passivating of welding joints and the heat affected area of welded stainless steel or inox fabrication. Pickling paste is applied with a special acid resistant brush. Pickling gel or paste has adhesive capacity and can be applied on vertical surfaces and formations or corners without any risk of running or drying. It is useful for spot treatment of welds and other intricate areas that require manual detail.

- A) Pick and Pass Gel (Paste)

5. Passivation

Passivation is a chemical treatment with an acidic process that removes free-iron and other contamination from the stainless steel while simultaneously promoting the formation of a passive chromium oxide layer to act as a barrier to further corrosion. Stainless steel contains enough chromium to undergo passivation by forming an inert film of chromium oxide on its surface. Chromium produces a thin layer of oxide on the surface of the steel the passive layer that prevents surface corrosion.

- A) Pick and Pass P.

6. Neutralizer

Neutralizer solution liquid alkaline solution to neutralize acid stainless steel pickling products and / or acidic surface after pickling and passivation. Neutralizer is the best way to ensure you are getting all of the pickling and passivation solution off your parts.

- A) Pick and Pass N.

7. Weld Cleaning Machine

The unique WELD Cleaning Machine devices are capable of quickly removing discoloration on welds while passivating stainless steel in one action without the need for aggressive substances! It does not leave any marks, such as white stains or color differences, meaning that it requires no further finishing and saves a lot of time.

Due to the 100% duty cycle, continuous voltage regulator and 3 power settings, the WELD CLEANING devices are by far the fastest weld cleaners available on the market. The light weight, robust and waterproof plastic casing makes it an optimum solution for use in any environment. Due to its fast, safe and residue / trace free operation, it is by far the best method in comparison to gel, paste, abrasive and pad type weld cleaning systems.

WELD Cleaners use a carbon fibre brush. Essential in this process is the quality, cost and lifecycle. Atc supplies the most economic carbon fibre brushes, due to volume; a premium quality carbon fibre, after extensive research and testing resulting with a very long lifecycle delivering the lowest operating costs.

The quality of the brush and coupling system is continuously improved to achieve a faster exchange of brushes and longer lifecycle.

There are also adaptors available on which several brushes can be mounted to clean larger welds or surfaces in a more efficient way. They are supplied with an adjustable sliding shroud, which is made from high-quality Teflon to achieve a long lifecycle, keeps the fibres of the brush controlled, providing more cleaning power and increases the lifecycle of the brushes.

Read more

8. TC ARC CLEANER

Our standard TC ARC CLEANER is perfect for cleaning and passivating stainless steel welds. Stainless steel passivation is simple to achieve with our cleaning system!

Passivation is the generic term applied to procedures developed to remove the presence of metallic (free) iron from the surface of stainless-steel products.

The presence of free iron particles on the surface of stainless-steel products can cause the product to show rust spots which should not occur with a clean or “passive” stainless steel surface. A PASSIVE stainless-steel surface would have NO free iron particles which could potentially corrode or “rust.” In addition to removing heat color our weld cleaning machines simultaneously passivate.

Read more

WANT TO KNOW MORE ABOUT OUR SERVICES

With over 20 years of in-depth experience, ATC delivers cost effective & efficient solutions and can be your ideal

partner for all your metal coating and finishing requirements.