Nickel

D Crown

Electrolytic Nichel

Nichel Chips

Purity : the purity of nickel chips is > 99.98% with its special shape, the nickel chips go down perfectly into the baskets, and are evenly distributed in the titanium baskets. Its shape prevents bridging information and ensures a constant anodic surface. It is safe to handle, having no sharp edge.

Chips are disc-like in shape, with a typical thickness of 4-6mm and diameter of 17-22mm, making this anode material suitable for plating from titanium baskets with standard mesh sizes.

Its advantages are:

· Consistent quality with purity above 99.98%

· Very competitive prices with a non-cut shape

· Great ease of filling titanium baskets

· Easy handling with small bags of 10 kg

· Filling fluidity: no bridge in baskets

· 100% nickel use, no waste

· Less current density required than electrolytic nickel, energy saving

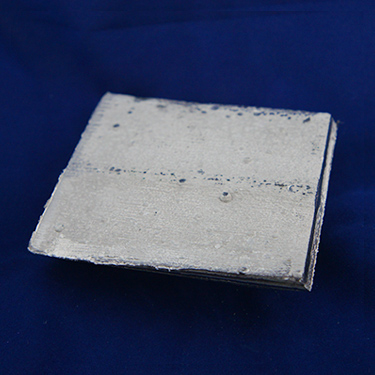

Nichel Tablet

Nickel TABLET usage gives a positive result for the control of the coating thickness and obtaining a better surface in contract materials with unknown steel composition, possibly composed of different steels. The highest zinc coating is reached when the silicon in the steel is 0.04 to 0.12% this range is called the Sandelin Curve. It Increases bath flow. Minimizes local coating differences. Provides a homogeneous appearance.

Benefits :

- Reactive Steels

- Prevents high coating thicknesses

- Prevents dark grey coatings

- Prevents peeling of coating

- Increase the coating homogeneity

- Zinc saving from 5% to 15% in weight

- Increase Coating ductility

- Smoother and brighter surface finish.

- Increase the fluidity of the Zn bath.

- Aesthetical coating appearance