Hot Dip Galvanizing

Hot Dip Galvanizing

Hot Dip Galvanizing

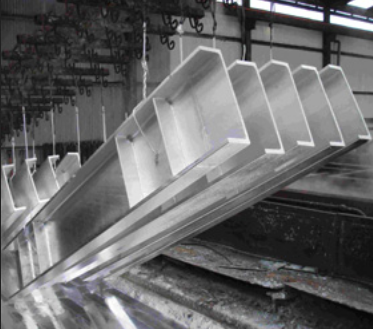

Hot-dip Galvanising is the process of immersing a steel or iron piece of metal in the molten zinc bath and heating it at 449° C which results in the deposition of a thin layer of Zinc on top of the base iron or steel metals forming an iron-zinc and steel-zinc alloy. Hot-dip galvanization uses chemicals like Zinc ammonium chloride as flux which is applied onto steel objects to avoid the corrosion of clean steel by the atmospheric air. This process exclusively uses Zinc as it has a high corrosion resistance tendency which makes it last longer, protecting the metal surface.

Hot Dip Galvanizing

Hot dip galvanizing chemicals

Acid

Degreaser

Alkaline

degreaser

Acid Inhibitor (Fume suppressant)

1. Acid Degreaser MSP

2. Acid Degreaser MSH

In hot dip galvanizing products, we have many different products in alkaline based degreasing products for use in hot-dip galvanizing. In alkaline degreaser profile customer can select products based on soil, scale and oils on steel.

1. Toughclean K 200

2. Toughclean DS

1. Inhibitor.

2. Inhibitor plus.

Galvanizing fluxes

The pre flux protects the work from further oxidation, thus resulting in prepared surface for galvanizing.

Galvanizing fluxes are formulated for accelerated speed, minimal fuming, less ash for uniform zinc coats. It is in solid and solution form which is used in the coating of tube, pipe, wire, small parts such as bolts and nuts, fencing in many parts. Flux is formation of high quality, adherent galvanized coating. It is a combination of organic and inorganic based surfactant, additives with wetting agents and salts of zinc ammonium chloride.

1. Water flux (a) Galvaflux R (b) Galvaflux Ni

2. Blanket flux (a) Galvaflux BL

Passivation

Nickel Tablets

Basic Chemicals

Passivation is done after galvanization of steel. Passivation solution contains special additives which avoids white rust on galvanized steel,

A.Trivalent Chrome Passivation

1.Tripass 402.

2.Tripass 100

B.Chrome free Passivation

1.Ramoline CF 21

2.Ramoline CF 13

Zn-Fe reaction. Nickel tablets have successfully been used in many plants all over the world. It is an easy and cost-effective way to maintain Nickel in the Zinc kettle. Ideal product to reduce your monthly consumption of Zinc. It improves the appearance of galvanizing items and results in smoother and brighter surface finish.

- Zinc Chloride

- Ammonium Chloride

- Liquor Ammonia

- Hydrogen Peroxide

- Glycerin

Zinc and Metals

Zinc is the most corrosion resistive metal on earth which is its prominent use in metallurgy. Using zinc to make zinc alloys is it's second most prominent use. Copper alloys of zinc and other metal alloys with zinc are used in automobile industries, electric industry, and many others.